Reactive Dyes

HE Dyes

These dyes posses higher exhaustion and fixation efficiency, which results in appreciable, cost reduction in comparison with conventional reactive dyes particularly for deep shades. These dyes are less sensitive to salt concentration time temperature and M:L ratio. These are largely employed for dyeing Cellulosic Knitting Fabric and Cellulosic component in Polyester/Cellulosic fiber blends be exhaust dyeing method at 80 – 85 C. These dyes are suitable for dyeing Hosiery, Knit Wear and Blends where Cellulose part of Polyester/Cellulose is to be dyed. High Fixation & high Tinctorial values hence economical to use. Excellent reproductively & good compatibility.

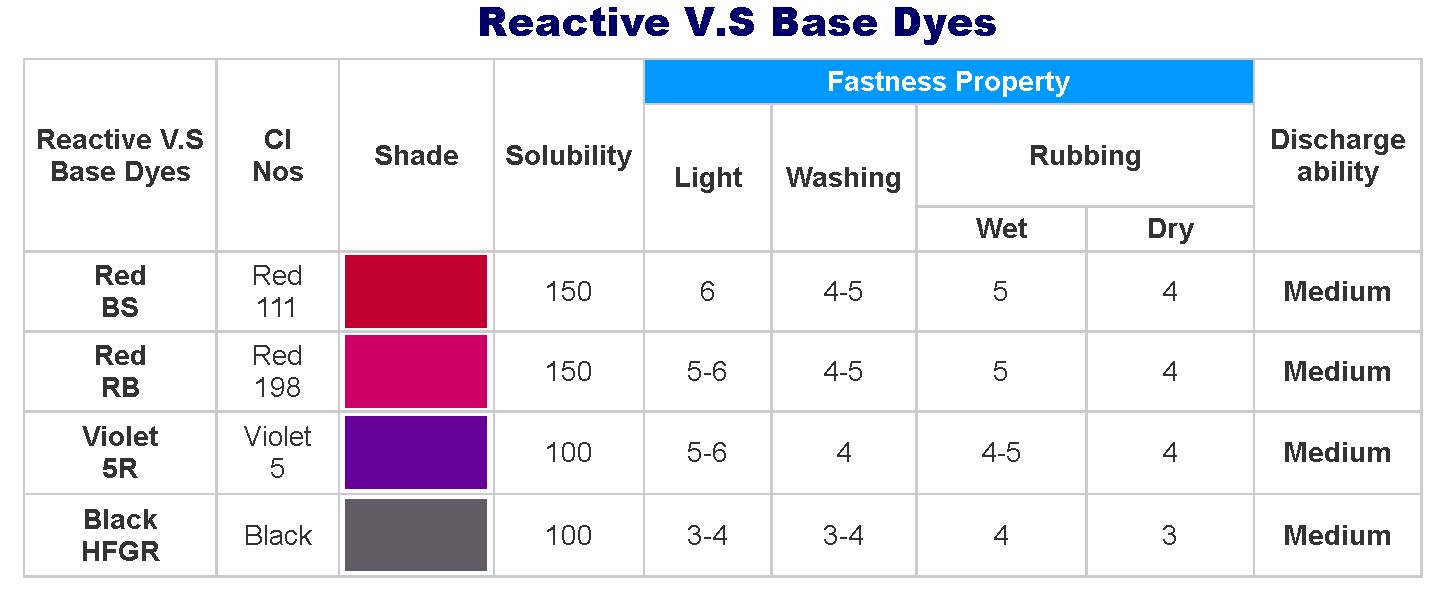

V.S.Based Dyes

The main characteristics of these dyes are completely dischargeable as well as suitable for white and color resist printing. The infixed hydrolyzed dye has no affinity for Cellulose hence No Tinting of white ground in printing. High Fixation since more than two redicals are bonded resulting in an increasing dyeing yield. Most suitable for once bath pas batch dyeing method using sodium as an alkali.

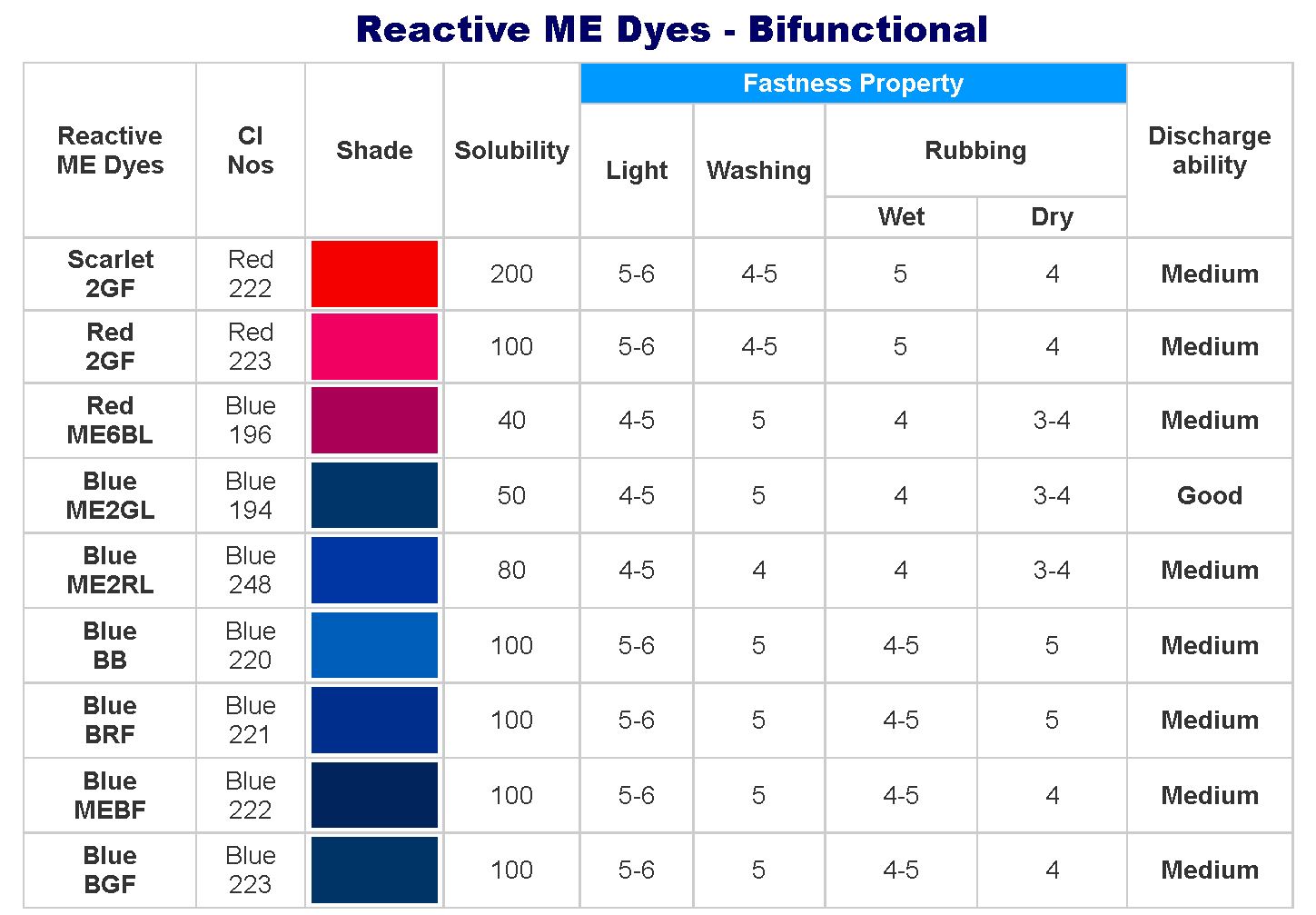

ME Dyes (Bi-Functional Dyes)

Low temperature, high exhaust and reactive dyes suitable for dyeing, padding and printing of all types of Cellulosic material. They give highly reproducible dyeing because of better alkali stability if low sensitivity to temperature.

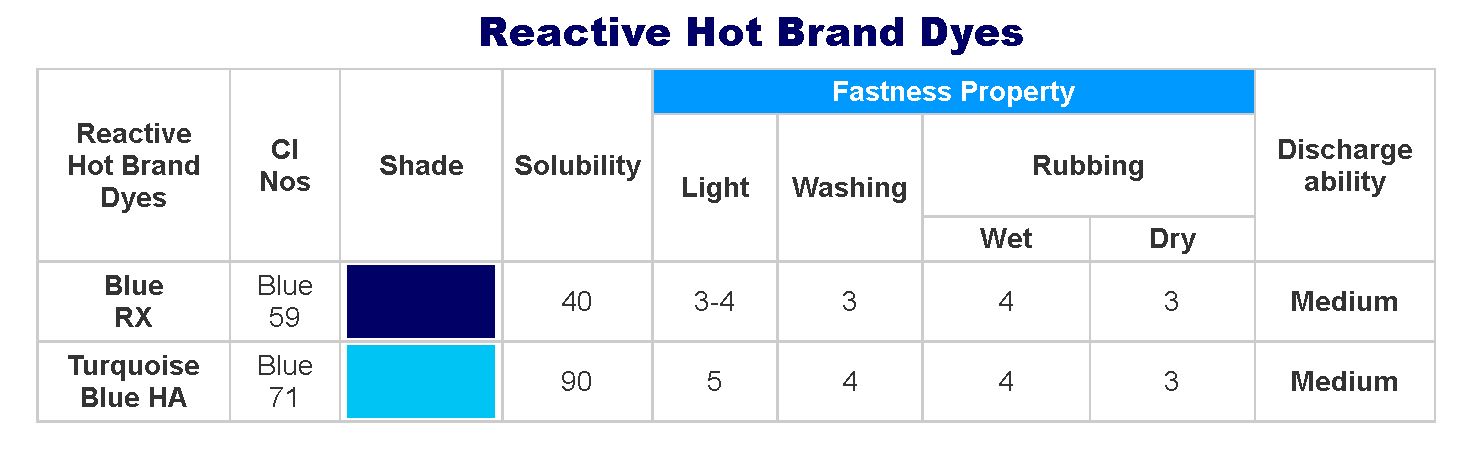

Hot Brand Dyes

Suitable for printing Cellulosic & Viscose Fabric, these dyes are fixed at 100 – 150 C by steaming. Due to the reactivity of these dyes the stability of print paste in presence of alkali is very good. Also due to low instability the hydrolyzed dyes have least tendency to stain adjacent white portion in the print hence it is very useful in printing of Cotton textiles.

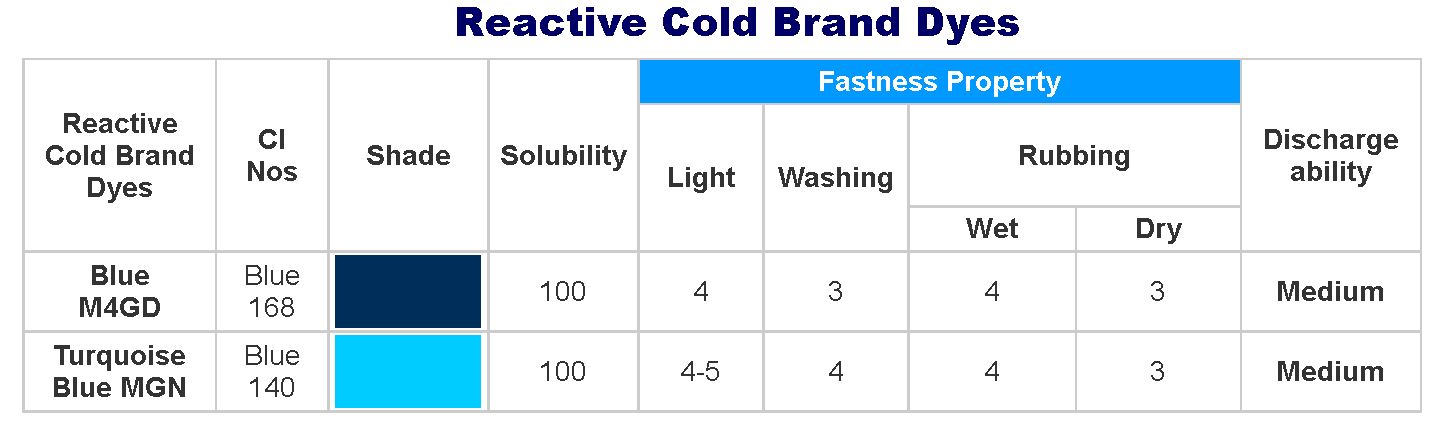

Cold Brand Dyes

Fiber dyes, which are characterized by simplicity of dyeing which are exceptionally brilliant with good Light Fastness.